New Production Photos

They are here folks!

And whilst they are not the final final backer ready copies, they demonstrate just how far we have come with our new production process.

New Moulds

Let's start with the dice, newly poured and popped out of their mould.

The left hand shot shows dice that have been made the traditional way. Once the resin has been cured, the dice are popped out and then the polishing begins. The cloudy effect is due to the rough edges of the previously used, mass mould.

The right hand shot shows a goddess dice popped out from one of our new moulds. The cloudiness has gone and the overall quality of the dice is already significantly improved.

The newly moulded dice then has the sprue shaved off and the final face polished before it is ready to be painted. Throughout the process each dice is kept separate to keep the surfaces of each dice protected.

Dead Centre (2.0)

Now with the new curing process the initial results are very promising and we are currently producing 1,000 dice, of different colours and finishes to ensure consistency.

Resin Quality

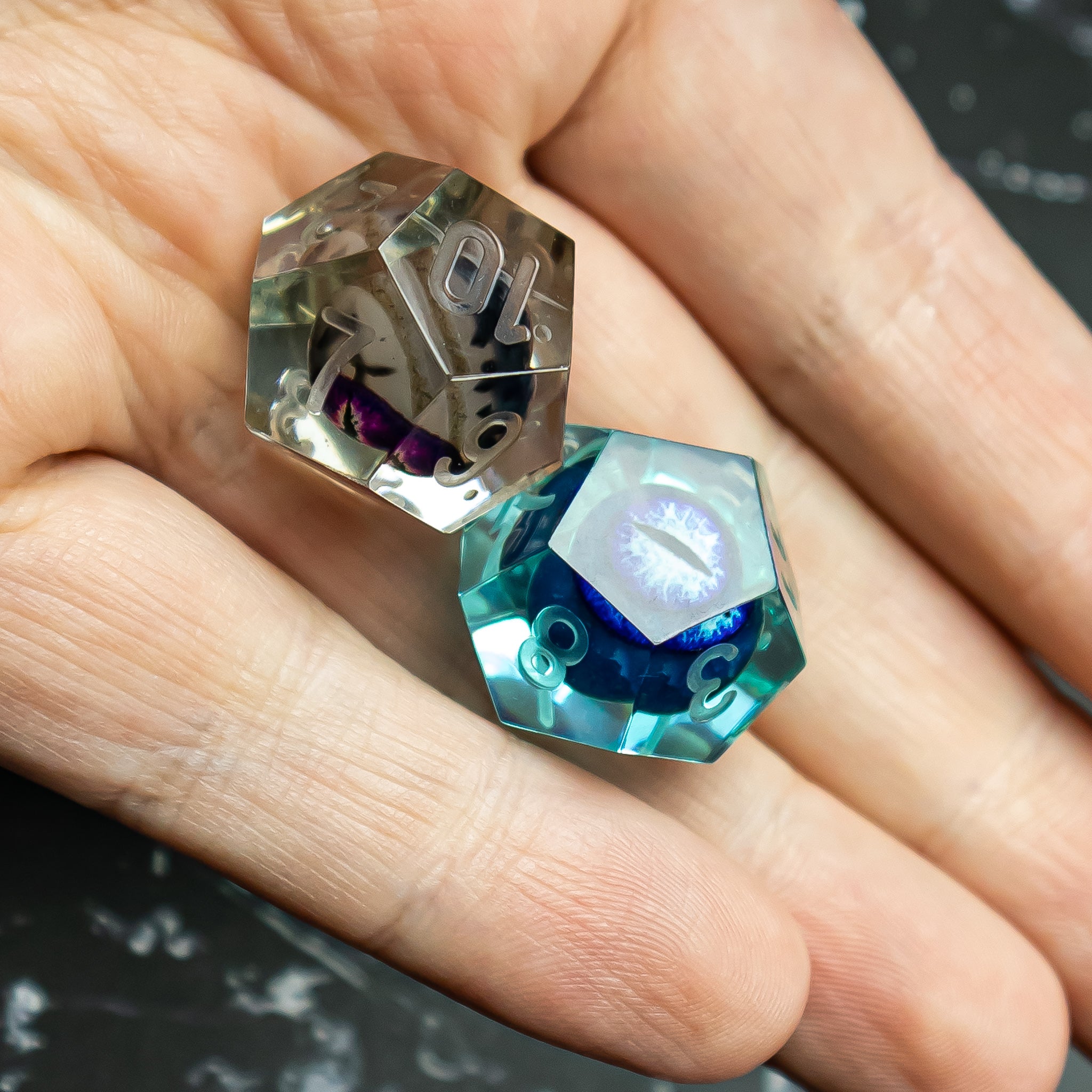

As well as upgrading the mould, to ensure a more perfect finish, we have also upgrade the resin to ensure an overall better quality of dice. Here are two examples, before the 'pips' are etched onto the surface and before the numbers are painted, to show the clarity off in full.

Dice Numbering

As part of the tumbling process in the traditional manufacturing method, the dice are placed in a large drum with small pieces of soft wood. Whilst this technique rounds the edges that we are all used to, it can smudge and damage the newly painted numbers, leading to a rough finish.

To ensure our numbers stay sharp and easy to read, we have etched deeper numbers with a more pronounced font. We have shown below a finished rounded edged d12 against a new sharp edged blue d12.

As soon as the new dice are ready we will show the final version up here, painted and in their respective boxes as soon as they are available.

Production and Delivery Timings

Having created a brand new production process for the Dragon Eye Dice, the new timelines that have come from the factory are as follows:

1) Final approval of production process (1-2 weeks)

2) Production of the full order (5 weeks)

3) Delivery of finished dice to Portland (3 weeks)

4) Fulfilment to Backers (2-3 weeks)

On the basis that we are now the second week in July, we see production being completed by the end of August and the fulfilment starting at the end of September.

These timings are estimates and there are several things we are looking at with regards to shipping that may well expedite the process, such as air freight. We will keep looking at prices and options and update here if anything deviates from this timing set out here.

Thanks for reading!